Top

Locks

Boats

Pound

Stop planks

Lock gates

Paddles

The “plug incident”

Why “Cuckoo”?

Winding hole

Turnover bridge

Feeder

Milestones

Bywash

– Ninety percent of my knowledge of canals comes from what I’ve learned since 2007, mainly about the Chesterfield canal at Worksop. There’s lots of things that I haven’t seen spelled out together in the same place, so I’ve tried to stick ’em here.

If I’ve got anything wrong or if there’s anything that ought to be here please let me know.

Canals

– The basic idea behind any canal is that it’s only necessary to move along level water against little or no current. Before canals the chief method of transporting goods in bulk was to use strings of pack horses. Most roads were unsuitable for wheeled transport.

– Chesterfield canal was planned by James Brindley who died in 1772 about a year and a half after construction was begun. Rather than relying on embankments and cuttings, he designed the route to follow the natural contours of the land as much as feasible. Obviously, where large height discrepancies occurred, artificial means were required. Climbing or descending slopes was achieved by using locks. In this way raising required no effort by the horse (or engine) as water would do the work. All working boats on the Chesterfield canal were horse drawn, engines weren’t used until the leisure boaters arrived.

| Rise or fall(feet) | Rise or fall/mile(feet) | |

| Rother→Staveley | -40.82 | -11.66 |

| Killamarsh→Top Pound | 72.75 | 48.5 |

| Top Pound→Shireoaks | -92.5 | -92.5 |

| Shireoaks→Manton | -68.33 | -18.25 |

| Osberton→Clayworth | -50.07 | -6.00 |

| Gringley→W Stockwith | -21.49 | -6.60 |

Locks

– Essential components of a lock are the gates, holding the water back, and the paddles, allowing the water through and enough room between the two gates to allow a boat, or sometimes more than one, of course. There is normally one gate at the higher point of a lock and two at the lower.(why one gate/two gates?) The gates have long, seven to fifteen feet, arms to allow them to be pushed against water pressure and to counterbalance the weight of the gates;

– The arc below the arm usually has some kind of raised ridges allowing better foot grip.Tip: don’t pull or push the arm: hold it at arms length and fall back allowing your weight to do the work.

Gates are held in place and hinged very simply by metal straps bolted to the lockside. Wear is compensated by merely screwing the strap a little.

– Water leaves the lock through paddles in the bottom gates and enters through ducts in the bank around the top gate.(why the different paddles?) The paddles are opened and closed by hand using windlasses to operate a rack and pinion.

| – The gates have footboards to allow safe crossing of the lock. |

On locks above Cinderhill on the Chesterfield there are footboards only on top gates. (Wouldn’t that have been better wording?)

– Inside the lock itself are recessed ladders for crew to leave or enter the boat while it is in the lock. There are “stop slots” at each entry to the lock so that it can be closed off for repair or maintenance.

– The level in the pound above a lock is maintained by allowing surplus water to pass around the lock over a weir. These bypasses (properly called bywashes) usually intentionally involve some turbulence which serves to oxygenate the water.

–

An unfortunate necessity is the cill, this is the stone slope, sometimes with a wooden part, that joins the bottom of the lock to the bottom of the high pound. A boat entering a full lock has to ensure that it is clear of the cill before opening the bottom paddles. Catching the rear on the cill can potentially flood a boat by tilting the front below water.

Staircase locks

–  Sometimes Brindley felt the fall or rise was too great to be achieved using one lock, but too steep to allow multiple complete locks. The solution was to compress two or three locks by removing the pounds between.

Sometimes Brindley felt the fall or rise was too great to be achieved using one lock, but too steep to allow multiple complete locks. The solution was to compress two or three locks by removing the pounds between.

As the amount of water “lost” is governed by the largest individual rise or fall in a flight of locks, this was also economical of water. As shown on the right there would be little wasted water in descending, or ascending, such a system.

– On the Thorpe flight there are two double locks and two trebles. This flight was the first part of the Chesterfield canal to be built.

For those less familiar with such locks, full instructions are displayed at top and bottom.

– As a precaution against inadvertent misuse overfilling the intermediate lock(s), there are side weirs and spills, as shown here at Thorpe Low Treble.

Boats

– They might be barges but don’t ever call ’em that: they’re narrowboats*, Nb for short. There are also some boats on the canal that look like speedboats: these are to be referred to as “plastics” or “tupperware“joke.

Some boats, butties, are not powered, this means that they have to be pulled, either by a horse or, more commonly nowadays, by a powered narrowboat.

The maximum size of a narrowboat on England’s narrow canals is 70ft long by 7ft wide, dictated by the dimensions of the narrow locks. On the Chesterfield one or two locks (Stret & Shireoaks Middle) constrain the maximum width to 6ft 10in or even less.

The canal is maintained with the aid of a fleet of workboats most of which have specialised functions. Different workboats exist for bulk carriage, dredging and weed cutting; many of these are unpowered and towed or pushed by single purpose tugs.

Individually, of course, all boats, whether narrow, plastic, butty or workboat, have names at the owner’s discretion, and there are some strange ones out there.

*Except when they’re wide, then they’re widebeams but they can’t pass narrow locks. They could only get as far as Retford up the Chesterfield and then not often, if ever.

On the Chesterfield all working boats were horse towed. The rope, constantly wetted and dragged along the ground became coated in grit, this made it very abrasive. At several places along the canal the ropes have worn grooves in the stonework. At Highground bridge (below Deep lock) they are particularly noticeable.

On the Chesterfield all working boats were horse towed. The rope, constantly wetted and dragged along the ground became coated in grit, this made it very abrasive. At several places along the canal the ropes have worn grooves in the stonework. At Highground bridge (below Deep lock) they are particularly noticeable.

Pound

late 18th century: … in the sense ‘body of still water, pond’ (Oxford Dictioary 5 Nov ’11)

A canal pound is the stretch of level water impounded between two canal locks. ( Wikipedia 5 Nov ’11 [edited])

Summit pound

A summit pound is formed at a high point on the canal where all locks descend from the pound. Summit pounds are particularly important in canal design as every boat entering or leaving the pound causes a loss of water. Summit pounds therefore need an independent form of water supply, which may take the form of weirs on adjacent rivers, reservoirs or pumping stations. Common practice during canal design was to make summit pounds as large as practically possible, in order that losing a lockful of water would not lower the water level too significantly.(ibid)

The Chesterfield canal has two summit pounds: Tapton lock to the R. Rother fed by the river and Thorpe Top Treble lock to Norwood tunnel fed by the Harthill feeder.

Sump pound

The inverse of a summit pound is a sump pound. In contrast to a summit pound, a sump pound is a point where every boat entering or leaving the pound causes an addition of water.(ibid}

Hollingwood lock to Staveley is a sump pound.

Lock pound

A lock pound is one which lies between two locks which lie only a short distance apart. Water levels in these pounds are liable to fluctuate as the locks are used.(ibid)

There are many such pounds on the Chesterfield; see those between the three Shireoaks locks and on the Turnerwood and Thorpe Flights.

The fuller name of a lock is a pound lock.

Stop Planks

A stop slot at Morse lock.

– For maintenance, to minimise water loss, the canal can be “chopped up” into sections. Slots were made opposite each other in narrow parts of the canal, at locks, bridges or specially constructed pinches“pinch” is a word I made up- I have no idea what it should be*in long pounds, originally in stone but now metal, down which a series of planks can be dropped to hold back water. This allows repair or replacement of lock gates or patching of leaks.

* Pictures of a “pinch” on the Top Pound.

– Stret lock stopped off for inspection. →

Why do locks have two gates at the bottom but only one at the top?

– Several reasons:

- Weight: with large falls/rises the bottom gate would weigh a lot and require more effort to move. The weight of the gate is somewhat counterbalanced by the weight of the arm, reducing the strain on the hinge straps. Increasing the gate’s weight would require longer, heavier arms.

- Water pressure: the top gate only has to hold back the pressure due to the depth of the canal (it’s only the depth that affects pressure), whereas the bottom gates have to hold back the pressure due to the depth of the canal plus the fall in the lock. A single bottom gate would have to be much stronger and therefore thicker and therefore heavy to move.

- Money! Of course a full width lock gate would have required that the lock itself be longer to allow it to open with a boat inside. Locks aren’t cheap to build, so economics probably play a major role.

- As well as costing more, a longer lock would mean more water used per cycle – not a good idea.

(more reasons?)

Paddles

Paddle lock

– Paddles are the valves that let the water through into and out of the lock. They are most often hand worked using a “windlass“. In areas prone to vandalism they are protected by a locking device which holds a ratchet against a cog on the shaft.

– On the top gates they are in the side of the lock entrance and are known as “ground paddles“, whereas bottom gates have the paddles in the gate itself.

– Why the different paddle placings?

Morse lock bottom mechanism

– Bottom paddles seem obvious: all they have to do is let water out so it’s just a matter of opening a hole in the gate.

– The top gate, on the other hand, is higher, A valve in the gate would allow any water coming directly through to go into a boat.

A top (ground) paddle mechanism

– So, take the water round the gate and down below the boat. The water flows through the ground: they’re therefore known as “Ground Paddles“.

– Here’s a ground paddle being replaced.

– I understand that on some canals top gates have both types of paddles, the ground is used first and the gate paddle can be opened once the water is up to the level of the gate.

Did someone really pull the plug, or is it an urban myth?

– No myth, it really happened.

Why “Cuckoo Dyke”?

– The original boats were unique to the canal. Most boat trips were short, this meant that there was no requirement for overnight accommodation and hence no, or only a small, cabin or shelter. The “traditional” canal art is also missing. Who first called them “Cuckoo Boats” isn’t known(anyone know?) but the canal was named after them. It is supposed that other narrowboaters coined the term as a somewhat derogatory reference.

– The footpath following the towpath is called the “Cuckoo Way“.

– Dyke itself is a strange word: it generally means a wall or embankment to keep out water but can also mean the water itself.

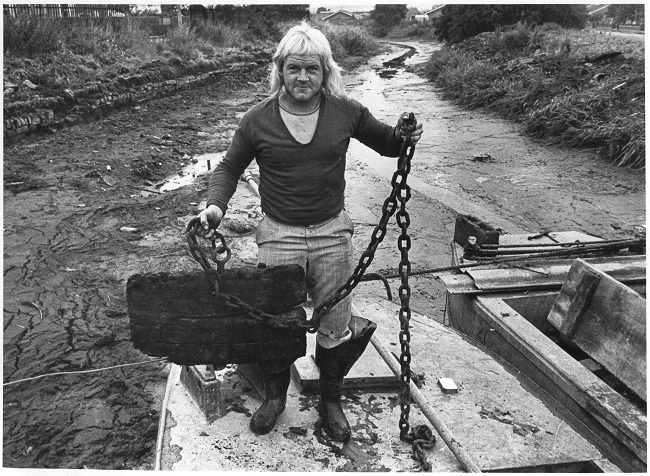

A traditional “Cuckoo boat” is presently being built at Shireoaks Marina by Canal Trust volunteers.

Winding hole

(it’s on the towpath side)

– Narrowboats are anything up to seventy feet long. The canal isn’t wide enough, normally up to 25 – 30 feet wide, for them to turn, so every now and then a special place is carved out where the canal widens up to allow turning. Winding holes are generally on the non-towpath side, so the wind might have been of assistance but generally long poles would have been used to punt the boat around. It should, apparently, be pronounced with a short “i” as in tin. The word possibly derives from the proto-germanic wandijanan. The German word “wenden” means to turn.

Turnover bridge

– A “turnover” or “snake” bridge is used where the towpath crosses from one side of the waterway to the other. Strictly speaking, it is where the horse (don’t forget all the craft on the working Chesterfield canal were horsedrawn) doesn’t need to be unhitched. Dog Kennel bridge at Kiveton Park isn’t now a true turnover, although it used to be, but Manton Turnover bridge west of Osberton is, as is the bridge at Bracebridge in Worksop.

There’s a real snake here and here.

Feeder

73.5 x 7 = 514.5 ft³

= 3204.75 Gallons

So, with the 65 original locks on the Chesterfield canal, the amount of water used for one boat to move from Chesterfield to the Trent would have been:

3204.75 x 65 = 208,308.75 gallons per foot of rise or fall.

208308.75 x 351.92(total rise/fall) = 73,308,015.3 gallons

seventy three million gallons!

That’s a lot of water!

– Water, as water is wont to, flows down. In addition canals leak. Water therefore needs to be supplied, especially at the highest point, but also at intermediate places where leakage make it necessary. On the Chesterfield the high point, on the western section, is the Top Pound between Thorpe locks and the Norwood tunnel. This water is supplied by “feeders”.

– A feeder is an artificial watercourse bringing water to a canal. The commonly have very little fall along their length; someone once said to me, of a now disused feeder at Norwood, that if you were to pee in the top, the bottom would be wet before the top had dried. There are several on the Chesterfield.

The Harthill feeder runs over two miles from Harthill Reservoir, as Broadbridge Dike, to the top pound where it enters via a magnificent cascade. (map)

Brancliffe Feeder in Broad Wood

The feeder entering below Feeder Lock

Feeder lock on the Turnerwood flight is where the Brancliffe feeder enters after its one and a half mile journey from the River Ryton at the foot of Lindrick Golf course.(map)

The Ryton feeder starts at the Canch in Worksop and feeds immediately below Kilton Low lock, it is less than one mile long.(map)

It has one or two unusual features:

- the stretch immediately downstream from the river is broad – possibly originally a fish pound for the nearby Priory?;

- quite a bit of the water leaves via another weir to rejoin the Ryton east of Priorswell Road;

- the feeder flows underground for a short distance after passing through what would seem to be housings for some kind of water wheel(?);

- the canal passes over the feeder, and the river Ryton, about two hundred metres west of Kilton Low lock below which the feeder enters.

At Retford next to the River Idle aqueduct there is a pumping station that feeds into the canal. Not strictly a feeder but …

(any more feeders?)

Milestones

– Every mile along the canal there is a marker stone indicating the distance from Chesterfield. I’d have thought it’d be measured the other way – the Chesterfield end is up to change – if it ever gets as far as Waterside it’ll surely mean that all the measurements will be out?

Many have dedications, although the vandals have taken their toll.

Bywash

The bywash is the channel which allows excess water to flow from an upper pound to a lower around a lock.

The obvious question is “why not allow the water to flow over the lock gates?”

This would obviously cut out a lot of work and require less land.

-

- Reasons:

- Without a bywash it would be impossible to drain locks to allow for maintenance.

- Emptying a lock to allow a boat to enter from the lower level would take much longer and might not even be possible if the upper pound was well replenished.

- Boats would be inundated when they approached the top gate.

- Wildlife can use the bywash to traverse the canal.

- Tumbling down ‘steps’ or over gravels allows the water to be oxygenated.

Some bywashes on the Chesterfield Canal, notably those at the higher, first made, locks, are not stone lined, being clay and gravel based.

top marks for this ,understand bit more.hoping to buy narrow boat liveobourd when sel house in spain.if ilive long e

LikeLike